Impulse Printing™

A revolutionary new printing technology

Micron sized features

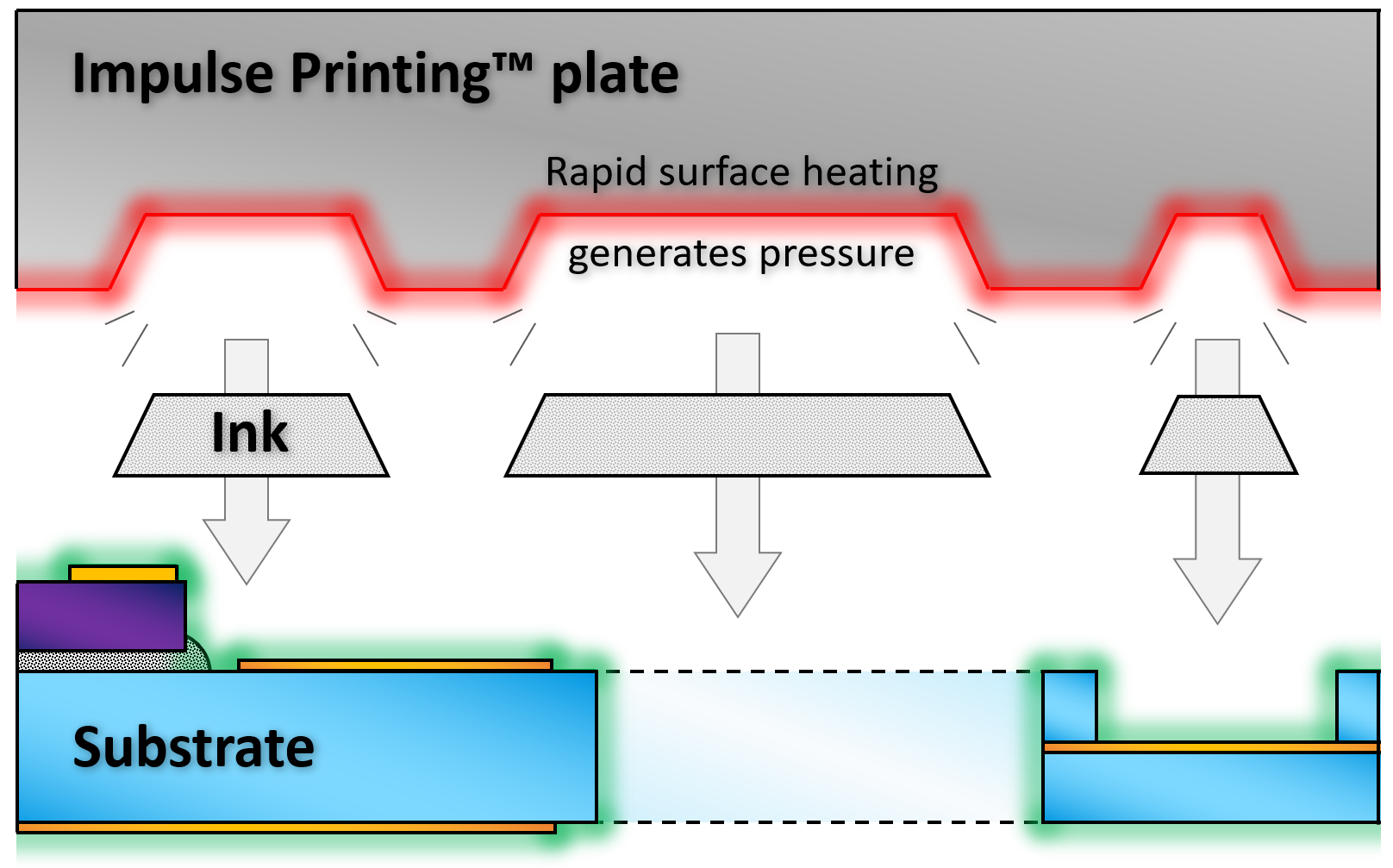

Impulse Printing™ starts with a custom filling system which fills grooves in a plate under high pressure. The plate is then rapidly heated, transferring the complete pattern in under a millisecond.

The plate is made using a lithographic process, enabling high resolution down micron sized features. Selective heating makes it possible to perform local alignment between the pattern and a substrate.

Using a flat heater plate and a stencil print process, larger features can be made in the same machine.

Complex 3D INterconnects

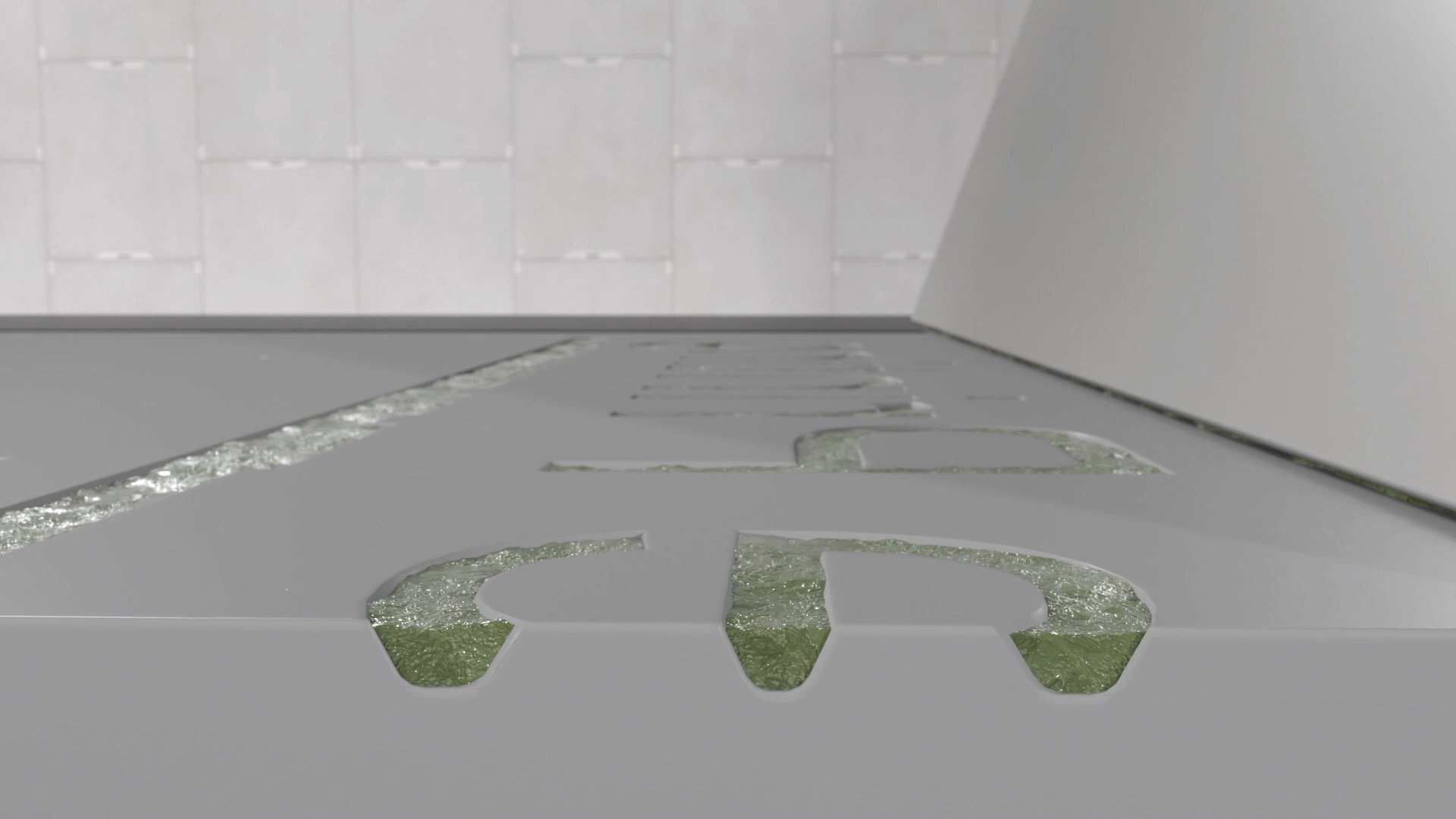

By printing a complete pattern all at once, never before seen applications are possible. In the video on the right, a wrap around connection is printed in real-time. Five lines are printed in an upwards direction. When part of the line hits the glass slide, the rest slingshots around two edges to create a front to back interconnection. In this demo, five heater zones are digitally controlled, with four lines arriving in an instant and one arriving later.

Bridging a 2mm gap.

Wrap around a 1mm thick glass slide.

15 and 20 micron width prints.

Printing on top of a 1mm high chip.

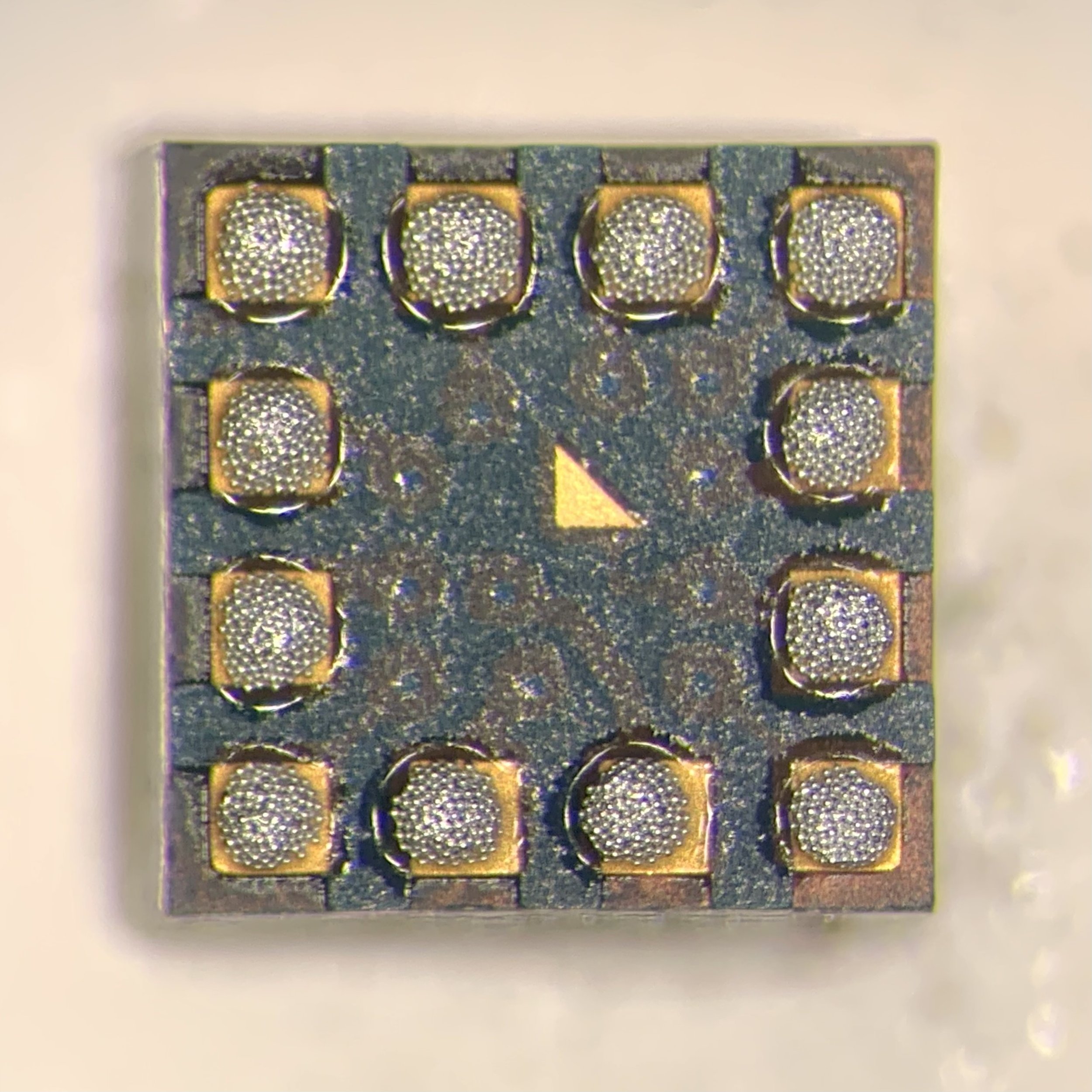

Solder paste at 1.3mm print gap and 300μm pitch.

Solder paste droplets on a 2x2mm LGA package.

Get in touch

A process development tool is available at FononTech, compatible with a wide range of materials air bearing stage allows precise substrate handling and supports all development and pilot production activities.

Process development tools, printhead modules and printheads are currently shipping.

It features 256 individually controlled printing zones to enable multi-layer printing, local substrate alignment and redundancy.

Print Area: 128 x 128 mm²

Substrate vacuum chuck: 300 x 300 mm²